SLE3E Clip-on POE Ultrasonic Thermal Energy Flowmeter

SLE3E Clip-on POE Ultrasonic Thermal Energy Flowmeter

Brand : SiteLab

Certification: ISO9001,ISO14001, CE

Payment & Shipping Terms

Minimum Order Quantity: 1

Delivery Time: 3-5 working days

Payment Terms: T/T,Cash

Application

HVAC, heating,energy-saving monitoring, heat balance regulation,heating regulation,AHU room,thermal energy transformation,etc.

Highlight :DN20~DN80 mm Ultrasonic Thermal Energy (BTU) Flow Meter, No need to set up pipe material , precise measure flow and energy, plug and play,alloy reinforced body,POE power supply network cable interface.

Alloy reinforced version Clip-on POE Ultrasonic Thermal Energy Flow Meter

Flow Range: | 0.03m/s ~5.0m/s(0.1ft/s ~ ±16ft/s) | Accuracy: | ±2% | |

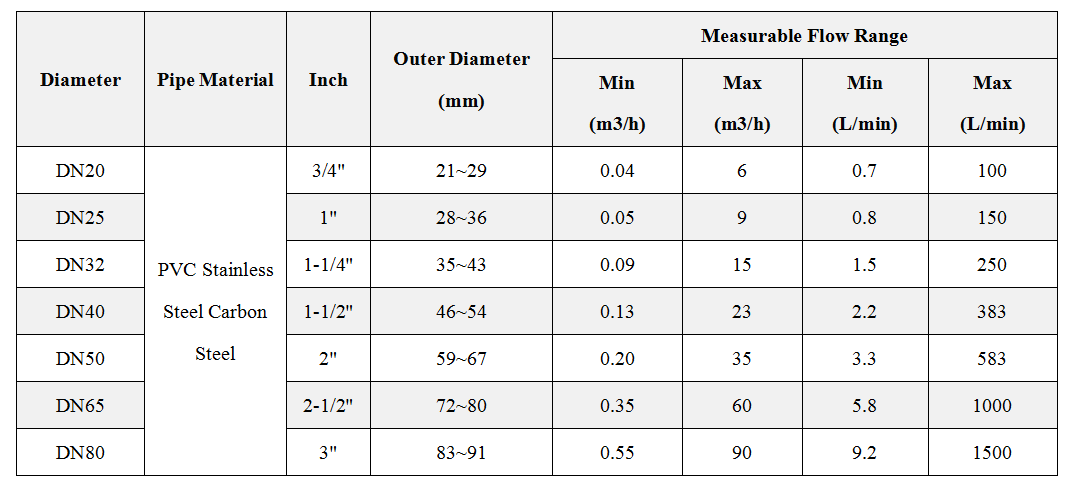

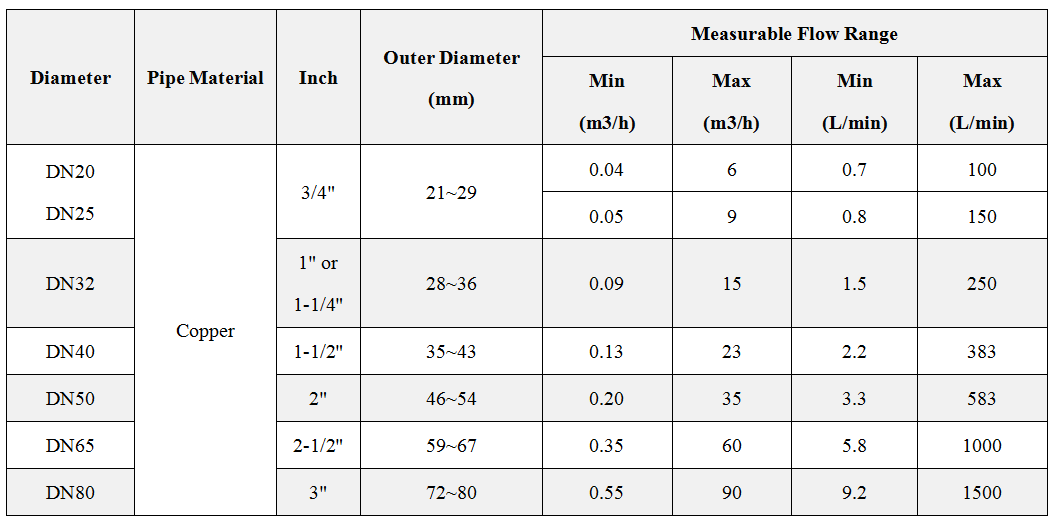

Pipe Diameter Range: | DN20~DN80mm | Measuring Medium: | Water | |

Pipe Material: | Stainless Steel/PVC/Copper/Stainless Steel | Communication Interface: | HTTP, MQTT Protocol | |

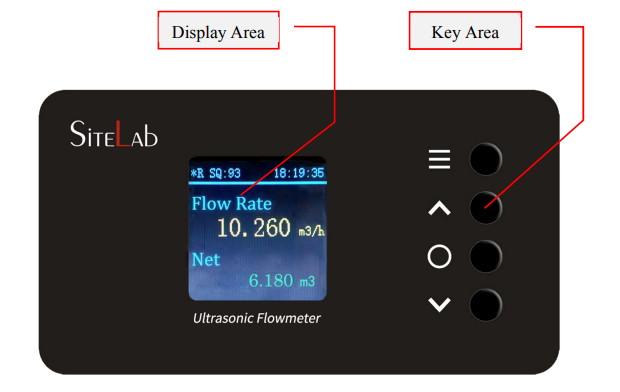

Power Supply: | 10~36VDC/500mA | Keyboard: | 4 touch keys | |

Display: | 1.44 " LCD color screen, resolution 128 * 128 | |||

SLE3E Clip-on POE Ultrasonic Thermal Energy(BTU) Flow Meter

Alloy reinforced & compact all-in-one POE ultrasonic thermal energy(BTU) flow meter

Introduction

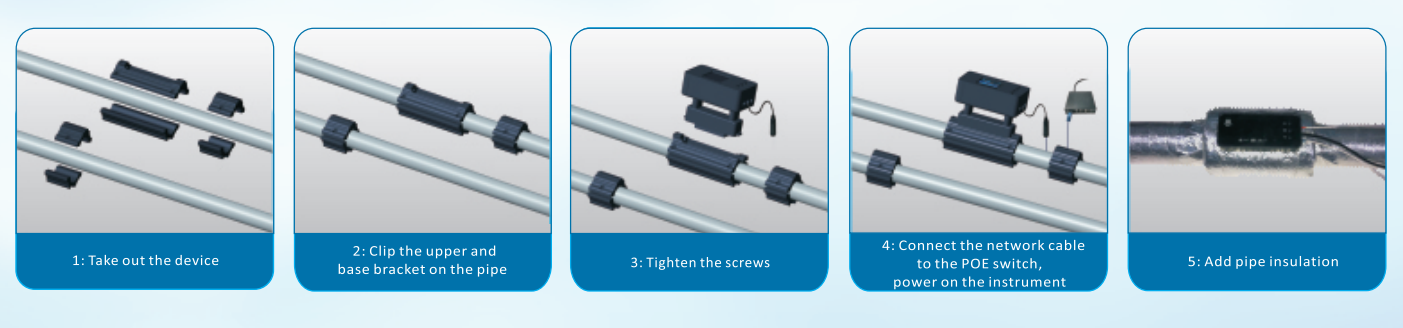

The SLE3E Clip-on Ultrasonic Thermal Energy/ BTU Flow Meter adopts the ultrasonic time difference measurement principle, and is combined with Gentos ultrasonic signal processing technology and unique flow and energy algorithm, to achieve accurate measurement of fluid flow and energy in the pipeline. The product has an integrated clamp-on structure design, which is simple and convenient to install. After four steps of operation,it can be powered on for measurement. During the installation process, there is no need to contact the fluid medium, and there is no need to stop production.

The instrument adopts POE power supply and Ethernet communication to realize cloud data storage. Users can access cloud data anytime and anywhere through mobile terminals or PC terminals to manage, analyze and query measurement data information.

Advantages

lPower & communication over Ethernet,safe and convenient

lAvailable on the MeterTube app and platform

lEasy installation, no damaging pipe

lNo adjustment,plug and play

lLCD color display

l360°rotation adjustable display screen

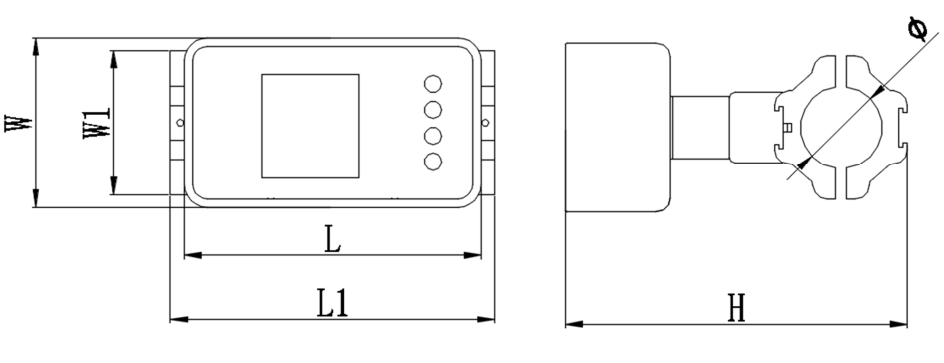

Transmitter &Temperature Transducer Dimensions

SLE3E Transmitter Dimension

Pipe Diameter Comparison Table Unit:mm | ||||||||

Model | Nominal Inner Diameter of Pipe | W | W1 | L | L1 | H | Ø | |

SLE3E | DN20 | 60 | 51 | 105 | 118 | 121 | 29 | |

DN25 | 60 | 56 | 105 | 118 | 128 | 36 | ||

DN32 | 60 | 63 | 105 | 118 | 135 | 43 | ||

DN40 | 60 | 74 | 105 | 118 | 146 | 54 | ||

DN50 | 60 | 89 | 105 | 153 | 159 | 67 | ||

DN65 | 60 | 102 | 105 | 153 | 172 | 80 | ||

DN80 | 60 | 113 | 105 | 153 | 183 | 91 | ||

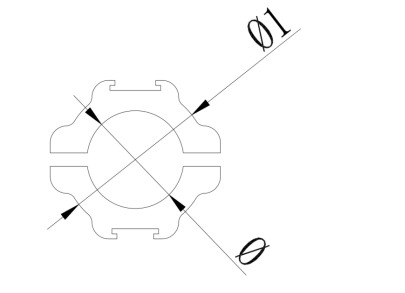

SLE3E Temperature Transducer Clamp Dimension

Pipe Size | Ø Pipe clamp inner diameter(mm) | Ø1 Pipe clamp outer diameter(mm) | ||

DN20 | 29 | 43 | ||

DN25 | 36 | 48 | ||

DN32 | 43 | 55 | ||

DN40 | 54 | 66 | ||

DN50 | 67 | 81 | ||

DN65 | 80 | 84 | ||

DN80 | 91 | 105 | ||

Professional Measure Single Material

Detectable Fluids

Installation